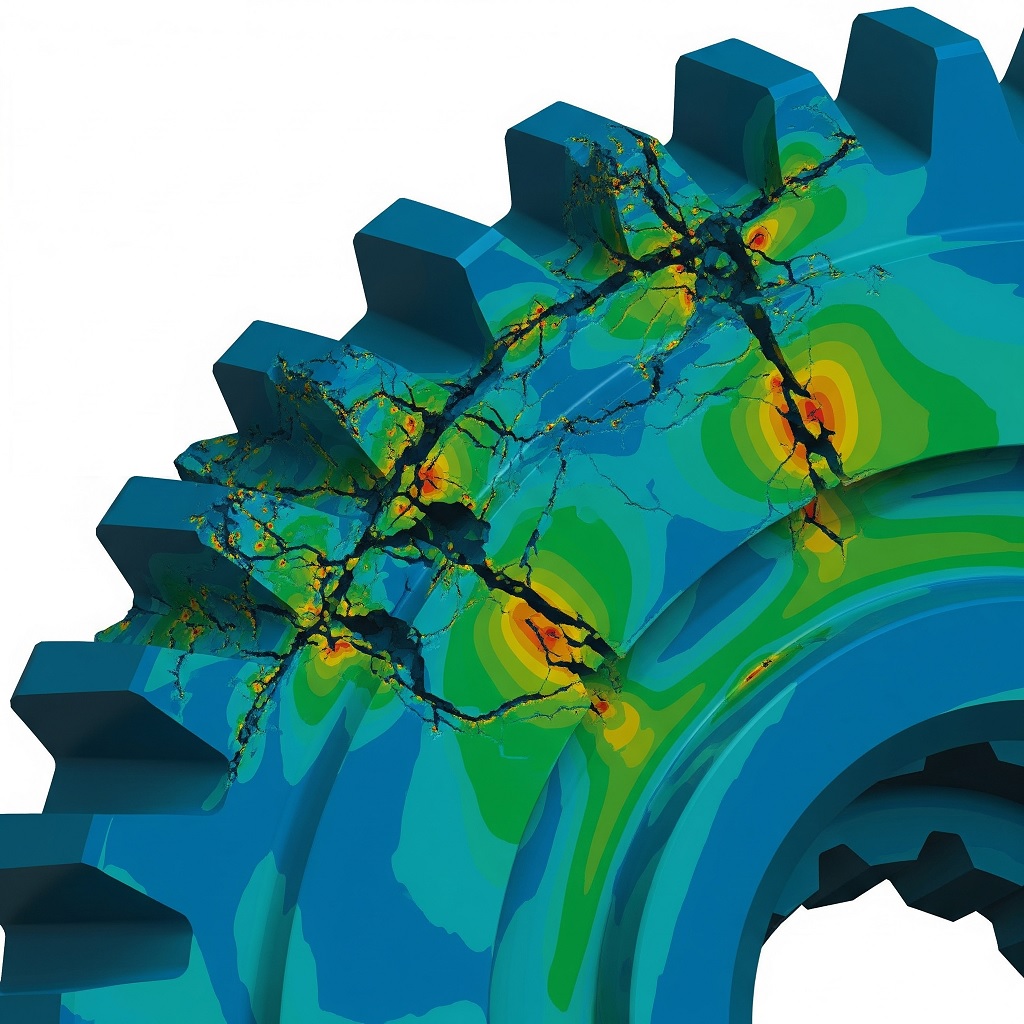

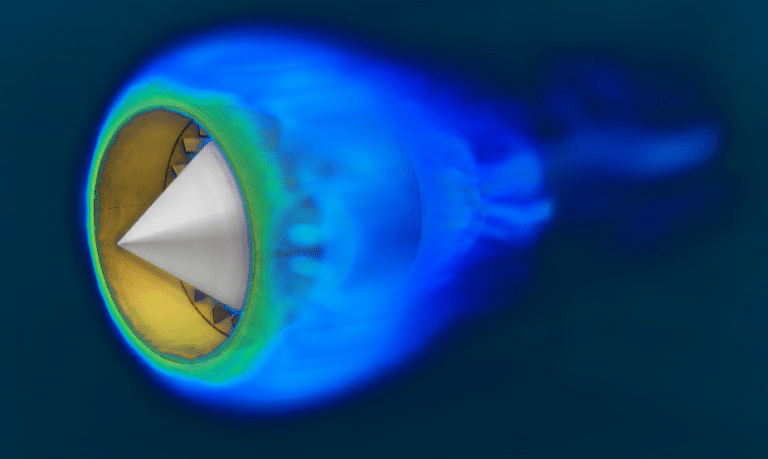

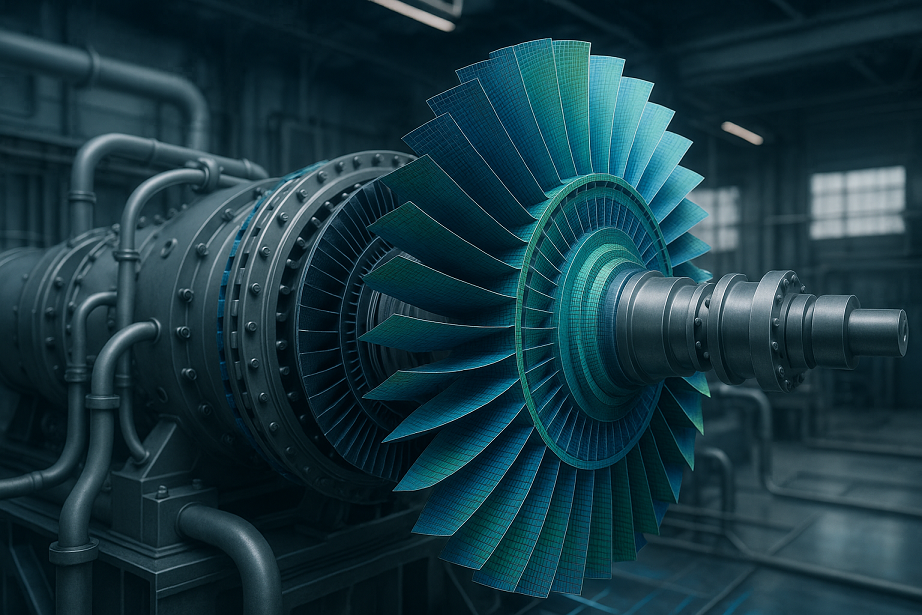

Failure analysis is a critical process that involves investigating and determining the root cause of a component or system failure. This requires a deep understanding of the many different failure modes that exist for any given system. Simulation Dynamics has extensive experience in failure analysis for various industrial and commercial equipment, including steam turbines, gas turbines, plastic structures, machine tools and fixtures, compressors, office equipment, pumps, turbine blades, mixing blades, rotating shafts, heating fans, exhaust hoods, rotors, turbines, and impellers.

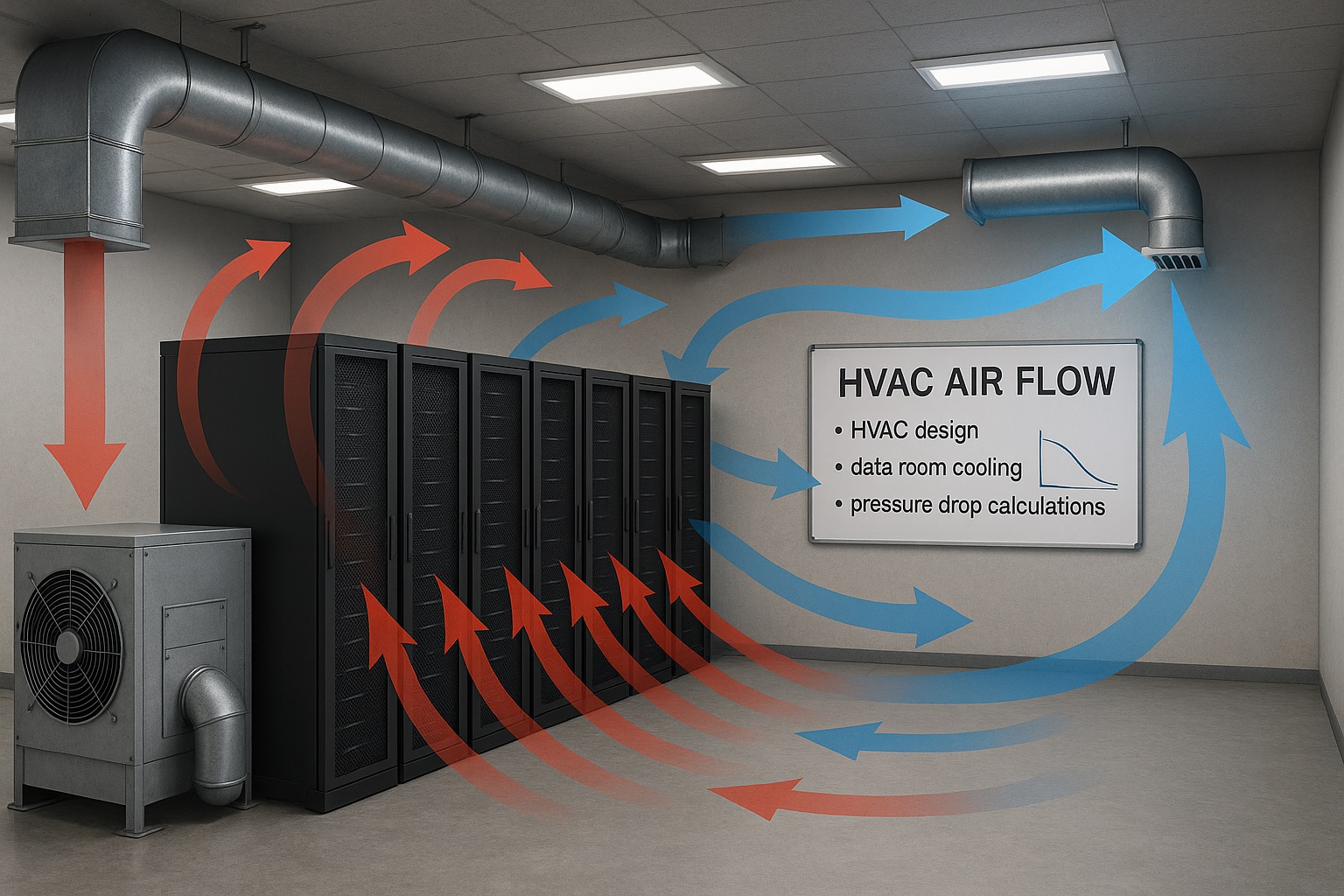

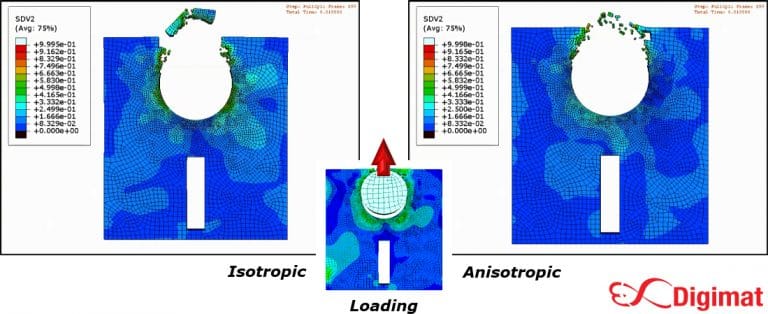

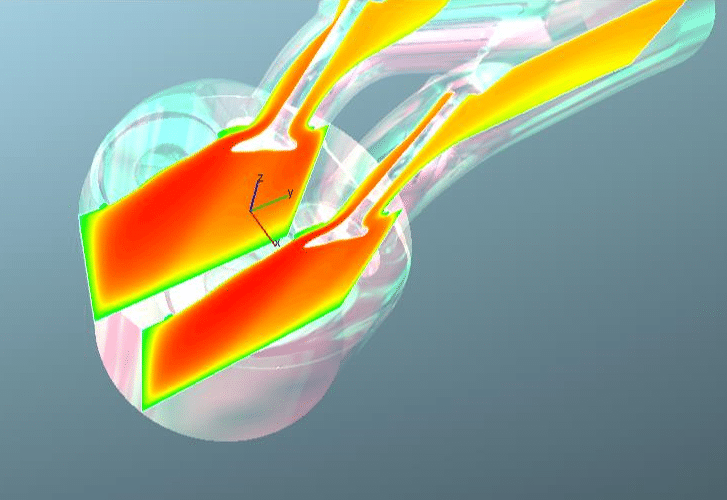

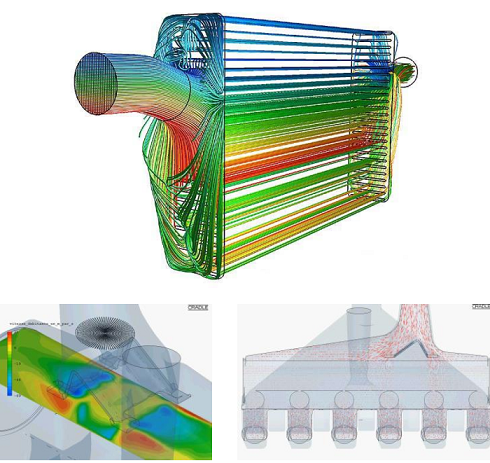

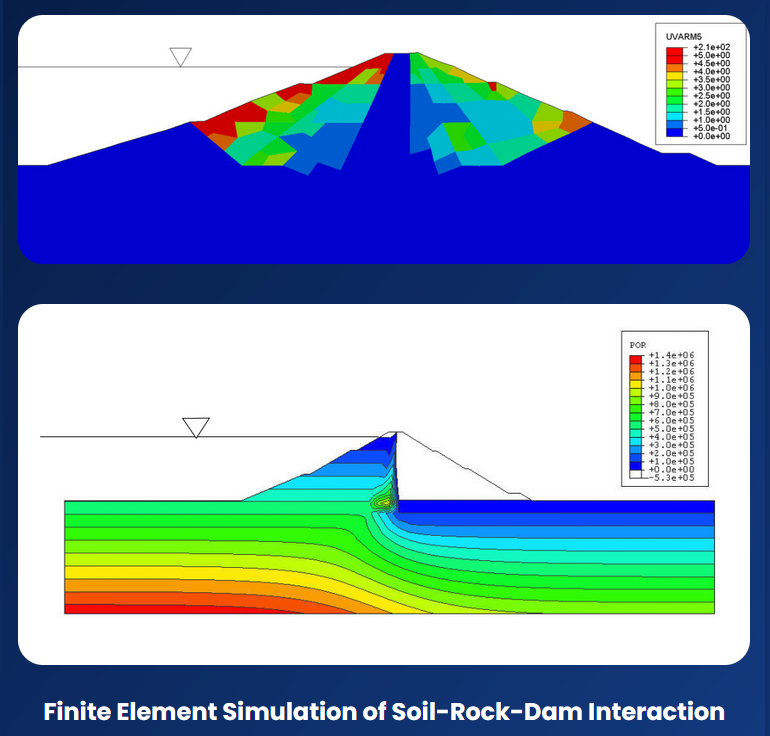

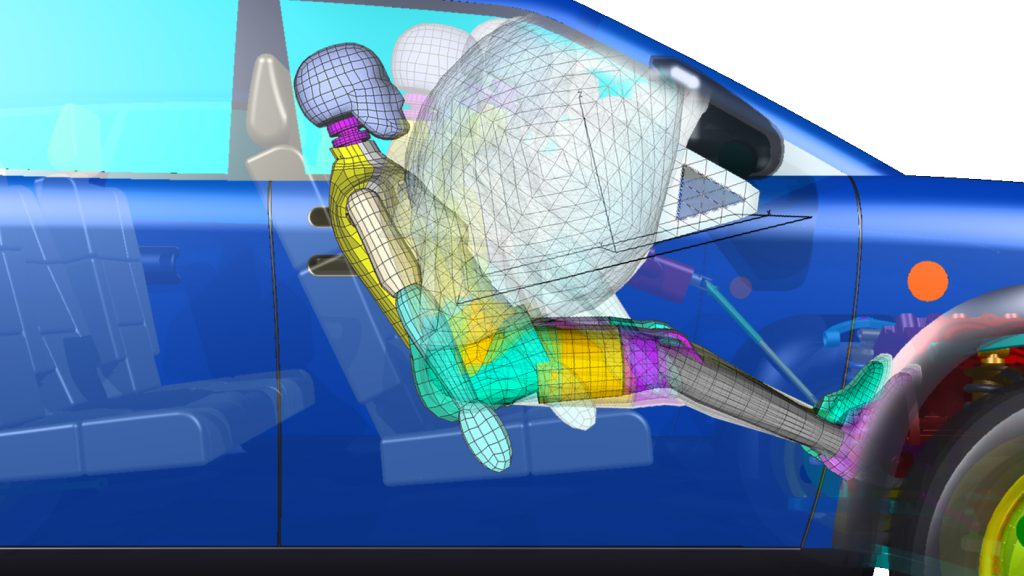

Simulation Dynamics's approach to failure analysis involves a combination of expertise in various engineering disciplines, such as materials science, mechanical engineering, and structural analysis, along with advanced analytical tools and techniques, such as finite element analysis (FEA), computational fluid dynamics (CFD), and fracture mechanics. This approach enables Simulation Dynamics to accurately diagnose and solve complex failure problems, as well as to provide recommendations for preventing future failures.

In addition to failure analysis, Simulation Dynamics also provides safety and stability analysis for lifting and handling equipment. This involves conducting tip-over stability analysis, which brings more insight into the stability of the equipment to improve future design. Stability evaluation and accident reconstruction are also performed in the virtual test machine to save costs and reduce development cycles. The effects of loading, wheelbase size, vehicle speed, top-heaviness, and inclination are studied to understand their impact on the stability of the equipment. This helps to ensure that lifting and handling equipment is designed to operate safely and efficiently, while minimizing the risk of accidents and failures.